The Situation

Oil companies might discharge produced water from their facilities to a local sea or inject it into a production or disposal formation, depending on local requirements. The discharged water quality at these facilities must be monitored for oil concentration to control process upsets and environmental issues. When oil field operators want to monitor the performance of their water treatment system, they have the choice to use the regulatory method or a field method. The field methods are generally faster and easier to perform but cannot be used for regulatory compliance.

Rigorous laboratory analysis methods, such as gravimetric oil and grease measurements or gas chromatographic methods, are not sufficiently sensitive to process changes and/or do not provide the required quick turnaround. Various quick analysis methods with different measurement technologies are available, but one needs to understand the methods and technologies when making a choice of an appropriate measurement method.

The Problem

The natural gas condensate produced at some production fields presents significant challenges for oil companies. Most measurement methods for hydrocarbons in produced water have reduced sensitivities to light crude oils or gas condensates due to high fractions of BTEX, highly water soluble hydrocarbons with no significant color. Some water treatment chemicals will produce interference because they are hydrocarbon-based chemicals. Solid particles, sand, rust and gas bubbles present more obstacles for accurate measurements.

The Solution

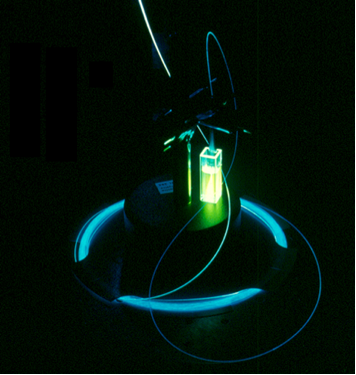

Field measurement of gas condensates in produced water can be achieved by some analyzers using deep UV fluorescence technologies, with minimal interference from other chemicals that might be present. UV technology, as used by the dual-channel TD-560 Oil in Water Analyzer, is ideal for field sample analysis of oil in water concentration. With its deep UV light source, the TD-560 measures crude oil and natural gas condensate from below 1 ppm to as high as 5,000 ppm in some cases.

Oil and gas condensates absorb the UV light and immediately emit a longer wavelength of light. The intensity of this emitted light is linear with the oil concentration and measured by a sensitive light detector. Solid particles, gas bubbles and most water treatment chemicals will not produce the fluoresced light and do not cause any significant measurement error.

The TD-560’s compatibility with all commonly used extraction solvents and multiple preparation procedures available allows field operators to choose the method that is best suited to their operations. The linear response of UV fluorescence to oil concentration in water produces good correlation to laboratory methods used for regulatory reporting. When quick field analysis of oil, light condensates or refined fuels is needed, UV fluorescence is the leading technology that operators can use to control their process with confidence.