Benchmark International has teamed several industry leading products to bring you a complete water treatment optimization solution.

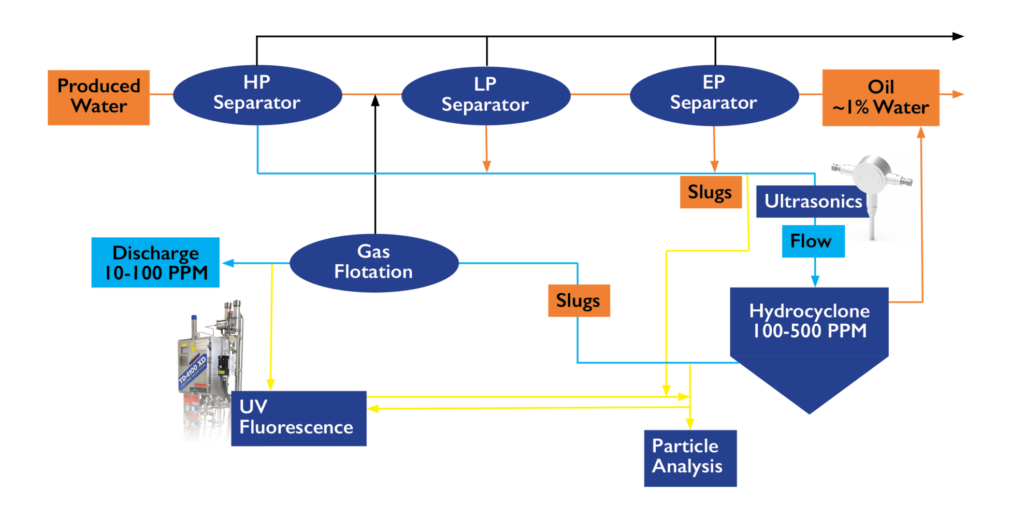

Produced water treatment systems, used for discharge or re-injection, can be greatly enhanced by adding ultrasonic and UV fluorescence monitors as well as an online particle analyzer.

- An ultrasonic monitor is inserted for early detection of high concentrations, or slugs.

- The UV fluorescence-based monitor adds the lowest possible detection levels at the point of discharge or re-injection.

- A particle analyzer is added after the separators for troubleshooting and injection monitoring.

The TD-2500’s ultrasonic probe offers simple insertion, with no process downtime. Its fast response time makes the TD-2500 ideal for detecting high concentrations—helping to improve water treatment efficiency and tune the chemical injection rate.

The TD-4100XD, designed for hazardous environments, provides cost effective, continuous, remote measurement of crude oil and natural gas condensate in water. Detection limits range from low ppb (µg/L) to high ppm (mg/L).

The MEx1A, from Process Imaging LTD, is an integrated analyzer and control computer for realtime measurement of oil concentration and particle size in process optimization.