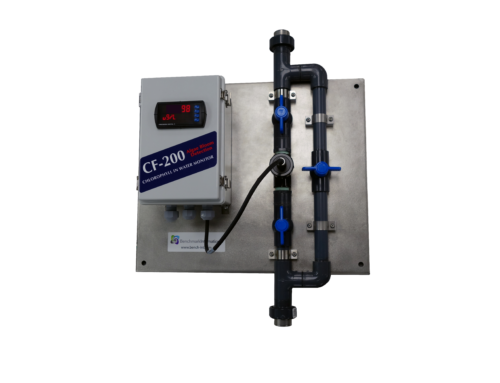

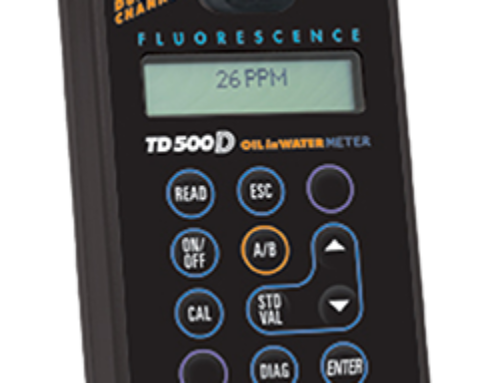

The TD-4100XDC is a closed cell version of the rugged, world industry standard TD-4100XD Oil in Water Monitor. It was designed for normally clean water applications or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It utilizes a clear tube flow cell to contain the sample water at pressure to prevent oxygen contamination in steam systems and to return the sample to the process at pressure. It uses a unique internal cell condition monitor to alert operations of the need for cleaning or to trigger the optional onboard cleaning system. As with all Turner monitors it includes a field validation method.

- Fluorescence measurement technology with lowest detection limits available

- Minimal sample conditioning plumbing hardware reduces cost

- Easy calibration with long term stability

- Low maintenance

- User friendly

- Ruggedized for harsh environments

- Internationally certified for hazardous areas

- Custom configurations, and wetted materials

- Steam condensate

- Boiler feed

- Normally clean water

- Cooling water

- Intake protection

- Dirty water with chemical cleaning if needed

Hydrocarbons detected

- Fuel oil

- Crude oil

- Other fuels and lubricating oils

- Phenol

- Styrene

- Most heat transfer fluids

- Aromatic chemicals

- BTEX

Detection range

- Fuel oil, crude oil 5 ppb-500 ppm in steam condensate

- Most other hydrocarbons