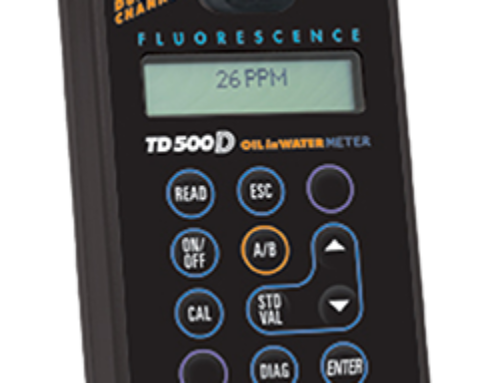

The TD-4100XDC General Purpose oil in water monitor is a lower cost version of the industry standard TD-4100XDC and is designed for use in non-explosive atmospheres. It was designed for normally clean water applications, or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It uses a clear tube flow cell to contain the sample water at pressure, prevent oxygen contamination in steam systems, and return the sample to the process at pressure. It features a unique internal cell condition monitor to signal the need for cleaning or to trigger the optional onboard cleaning system. As with all Turner monitors, it includes a field validation method.

Unique features

- Fluorescence measurement technology with lowest detection limits available

- Minimal sample conditioning plumbing hardware reduces cost

- Easy calibration with long term stability

- Low maintenance

- User friendly, with E09 electronics package

- Ruggedized for harsh environments, non-hazardous areas

- Custom configurations and wetted materials

- Steam condensate

- Boiler feed

- Normally clean water

- Cooling water

- Intake protection

- Dirty water with chemical cleaning if needed

Hydrocarbons detected

- Fuel oil

- Crude oil

- Other fuels and lubricating oils

- Phenol

- Styrene

- Most heat transfer fluids

- Aromatic chemicals

- BTEX

Detection range

- Fuel oil, crude oil 5 ppb-500 ppm in steam condensate

- Most other hydrocarbons