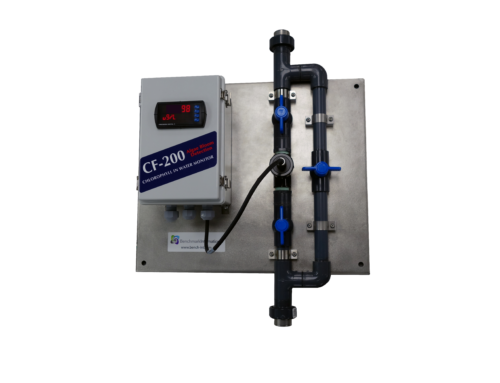

Most oilfield produced waters and other oily waste waters have high fouling potential for optical sensors. High cost ultrasonic cleaning systems only address the local optical path and not the entire sample system. Our clean-in-place (CIP) system addresses the entire sample system in the same way that CIPs are used to clean heat exchangers and other oily systems.

Features

- Chemically cleans the complete sample system from sample take off to the drain.

- Self-contained, with no chemical discharge while cleaning. All chemicals and waste are self-contained until drained.

- Pneumatic or electrical, manual or automated, explosion proof or general purpose. Can be fully controlled by the TD-4100XD with E09.

- Chemical choice and cleaning frequency dependent on the process water.

- Light weight/small footprint.

- One CIP can clean multiple sample lines.

- Add to any existing oil in water monitor.

- Lowest cost of ownership. Can be manufactured locally, with free supplied drawings.

With our more than 20 years of success in produced water applications, we know that making the measurement is only the beginning. Oil in water monitors must be maintained. Scale, solids, wax, iron sulfide, and crude oil lead the list of foulants. The start/stop action of systems with ultrasonics can make things worse by letting sediment settle or foulants plate out on the tubing/piping. Falling stream noncontact systems work great until the sample systems foul and reduce the sample flow.

A self-contained chemical cleaning system cleans the entire sample system and returns all chemicals to the supply tank for recycle on the next cleaning cycle. Customers report up to 12 months of use before refreshing chemicals. The specific chemicals and cleaning cycle time are determined based on the needs of the facility and the fouling potential of the produced water.