Refineries use a significant amount of steam in the process of distilling gasoline, diesel and other hydrocarbon products. Collecting and returning as much steam as possible saves on energy, water consumption and sewering costs. For some refineries 50% of the steam can be recovered.

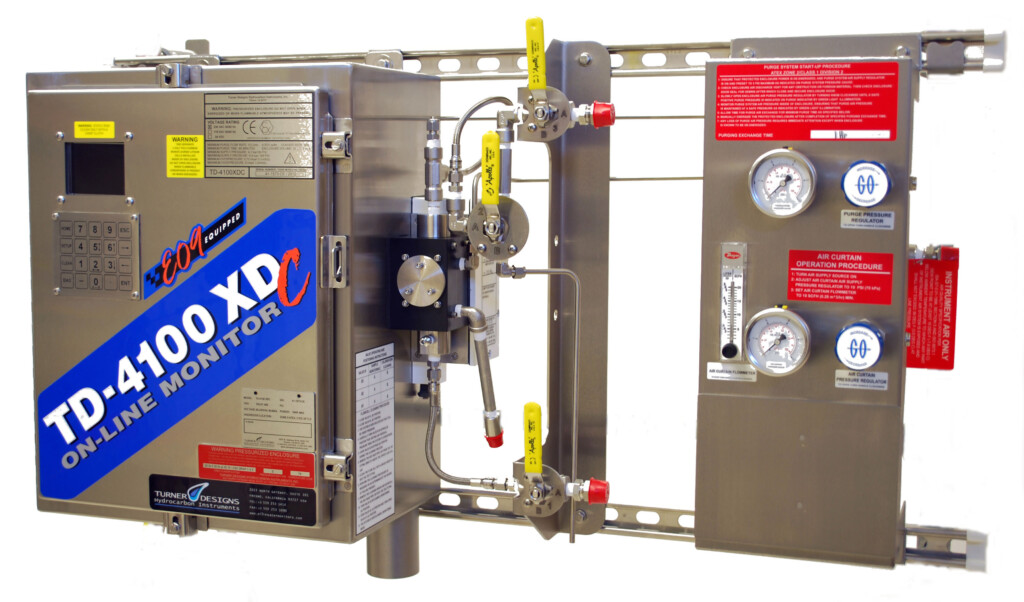

Because return steam can be contaminated by hydrocarbon leaks in the heat exchangers, refineries often need a monitoring system to alert operators when a hydrocarbon leak has occurred. The TD-4100XDC, TDHI’s closed-cell online monitor, is the perfect solution for detecting hydrocarbons in steam condensate.

TD-4100XDC Features

- Lowest available detection limits

- Low maintenance

- Long-term calibration stability

- Internationally certified for hazardous area use

- Custom configurations and wetted materials

- Minimal sample conditioning plumbing hardware reduces cost

- User friendly

- Ruggedized for harsh environments