Oil in Water Monitors

We are the worldwide leader in the application of field portable, laboratory, and online continuous process monitors and analyzers. We offer solutions for measuring and monitoring hydrocarbons, algae and dispersed or suspended particles in water. Our monitors are based in fluorescence, ultrasonics and imaging technology.

Our Featured Applications

Hydrocarbons

Some of the PAH and monoaromatic hydrocarbons detected by our monitors:

Applications

To read more about applications, select a link.

Technology

Benchmark Measurement Solutions instruments are based in UV and visible fluorescence technology. E09 electronics and a highly sensitive light detector allow hydrocarbons to be detected from the parts-per-million (ppm) to parts-per-billion (ppb) range. Compared with other hydrocarbon in water detection methods, such as ultraviolet or infrared spectrophotometry, the E09 electronics offer:

Benchmark Products

Find Solutions

The TD-2500 combines ultrasonics and a time-tested insertion probe to offer the ultimate in early detection of high concentrations, or slugs, of oil in waste water. Ultrasonic technology measures oil at high concentrations, typically seen after oil/water separation, is sensitive to droplets, solids or gas bubbles and is easier to maintain than optical technologies.

Features

- Detects high oil concentration slugs before separators

- Measures oil in water (10 ppm–30,000 ppm)

- Zero downtime sensor removal—process insertion with ball valve

- No moving parts, low maintenance

Plankton biomass in sea water can be variable by season, weather and other uncontrollable conditions. Industrial plants with sea water intake can be affected by high plankton concentrations. Reverse osmosis desalination systems can have high differential pressure, and when treated with chlorine, can have high disinfection byproducts in the membrane permeate.

Chlorophyll A is the primary pigment in algae. Its measurement in sea water is an effective method of tracking total plankton concentration.

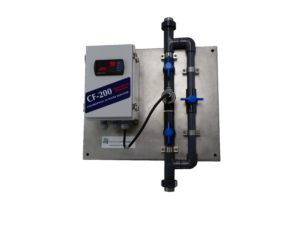

The robust CF-200 monitoring system consists of a probe, bypass assembly, display and transmitter for continuous measurement of Chlorophyll-A. The CF‑200 alerts plant operators of algae blooms to help prevent excess pressure drop or contamination of the permeate.

Benchmark Measurement Solutions proudly features the dual-channel TD-560 Oil in Water Analyzer. In addition to the optical channel found in the TD-550, suitable for crude and other heavy oils, the TD-560 adds a second channel for detecting lighter hydrocarbons, such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol. The TD-560 offers a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers.

Features

▪ Low cost per sample analysis

▪ Large full-color touch screen interface

▪ Advanced data logging and graphing capabilities

▪ Compatible with all popular extraction solvents and Benchmark’s No-Solvent Method

▪ Results can be correlated to official lab methods such as USEPA 1664A and ISO 9377-1

▪ Multipoint calibration and multiple calibration storage capabilities

Turner Designs Hydrocarbon Instruments is proud to introduce the new standard in grab sample oil in water analysis with the TD-550 oil in water analyzer. The TD-550 is suitable for crude oils and other heavy oils with a greatly enhanced detection range (low ppb to 5000 ppm) over most oil in water analyzers. Related product, the TD-560, includes the same optical channel of the TD-550 along with a second optical channel for detecting lighter hydrocarbons such as BTEX, gas condensates, gasoline, jet fuel, kerosene, transformer oils, styrene and phenol.

Features

- Low cost per sample analysis

- Large full-color touch screen interface

- Advanced data logging and graphing capabilities

- Compatible with all popular extraction solvents and TDHI’s No-Solvent Method

- Results can be correlated to official lab methods such as USEPA 1664A and ISO 9377-1

- Multipoint calibration and multiple calibration storage capabilities

The TD-120 Oil in Water Monitor was developed from more than 20 years of real-world experience in UV fluorescence technology. The TD-120 Oil in Water Monitor is resistant to dirty or turbid water influences that typically impact UV absorption or light scatter instrument measurements—allowing hydrocarbons, fuels, lubricating oils, heat transfer fluids, and crude oil to be measured at low ppm/ppb levels. The TD-120 Oil in Water Monitor also has a greatly enhanced dynamic range compared to most online oil in water monitors (up to 6000 ppm).

Features

- New auto-valve capabilities: temperature protection, fresh water flush, and process isolation

- Analog signal, alarm dry contact relays

- Optional sea water compatible wetted parts

- Minimal maintenance

- Low cost of ownership—no reagents or instrument air needed for operation

- Internal tablet interface for quick setup and calibration

- OEM opportunities

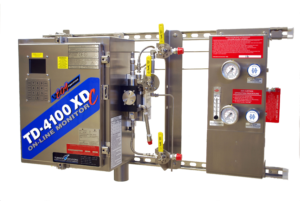

The TD-4100XD is a ruggedized version of the TD-4100 continuous online oil in water monitor. The XD is designed specifically for offshore oil production, refining, petrochemical, mining, and other industries that require robust online hardware for severe duty and hazardous area locations. The monitor is skid or wall mounted and constructed of 316 stainless steel. It also includes an external keypad for operation in corrosive environments. The TD-4100XD detects and measures crude oil, refined fuels, fuel oils, lubricating or hydraulic fluids, and aromatic solvents in water. Detection limits range from low ppb (µg/L) to high ppm (mg/L).

Why Continuous Online Monitoring?

- Continuous online monitoring provides the most responsive feedback loop for measuring hydrocarbons in water.

- Continuous monitoring is reliable, effective and recognized for its ability to improve process management for treating, discharging and detecting hydrocarbons in water.

- Compared to laboratory grab sample analysis, online monitoring provides cost effective, continuous, remote, operator unattended measurement of aromatic hydrocarbons in water.

The TD-4100XD General Purpose monitor is a lower cost version of the industry standard TD-4100XD and is designed for use in non-explosive atmospheres. It was designed for dirty water applications and uses our standard EZ Access noncontact flow cell for lower maintenance. Field validation is via our CheckPOINT™ solid calibration check standard.

Unique Features

- Fluorescence measurement technology with lowest detection limits available

- Minimal sample conditioning plumbing hardware reduces cost

- Easy calibration with long term stability

- Low maintenance

- User friendly, with E09 electronics package

- Ruggedized for harsh environments, non-hazardous areas

- Custom configurations and wetted materials

The TD-4100XDC is a closed cell version of the rugged, world industry standard TD-4100XD Oil in Water Monitor. It was designed for normally clean water applications or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It utilizes a clear tube flow cell to contain the sample water at pressure to prevent oxygen contamination in steam systems and to return the sample to the process at pressure. It uses a unique internal cell condition monitor to alert operations of the need for cleaning or to trigger the optional onboard cleaning system. As with all Turner monitors it includes a field validation method.

Features

- Fluorescence measurement technology with lowest detection limits available

- Minimal sample conditioning plumbing hardware reduces cost

- Easy calibration with long term stability

- Low maintenance

- User friendly

- Ruggedized for harsh environments

- Internationally certified for hazardous areas

- Custom configurations, and wetted materials

The TD-4100XDC General Purpose oil in water monitor is a lower cost version of the industry standard TD-4100XDC and is designed for use in non-explosive atmospheres. It was designed for normally clean water applications, or dirty water applications where fouling can be controlled by chemical injection or optional onboard cleaning systems. It uses a clear tube flow cell to contain the sample water at pressure, prevent oxygen contamination in steam systems, and return the sample to the process at pressure. It features a unique internal cell condition monitor to signal the need for cleaning or to trigger the optional onboard cleaning system. As with all Turner monitors, it includes a field validation method.

Features

- Fluorescence measurement technology with lowest detection limits available

- Minimal sample conditioning plumbing hardware reduces cost

- Easy calibration with long term stability

- Low maintenance

- User friendly, with E09 electronics package

- Ruggedized for harsh environments, non-hazardous areas

- Custom configurations and wetted materials

Online Particle Analysis

Benchmark Measurement Solutions is proud to offer industry-leading particle analyzers from Process Imaging, LTD. In addition to products benefitting from more than 20 years development and experience, Benchmark now offers a complete consultancy and project management service for exploration geochemistry, oil and gas fluid behavior in the reservoir, during production, water injection, waste water treatment and produced water injection projects.

Learn More

Read in-depth case studies and whitepapers for your business application.

Validation of saltwater disposal well treatment plants with oil in water sample analyzer

A detailed study of how high-frequency sample analysis can be performed at salt water disposal wells, using a portable TDHI analyzer. TDHI oil in water analyzer results correlate well with gravimetric method 1664A.